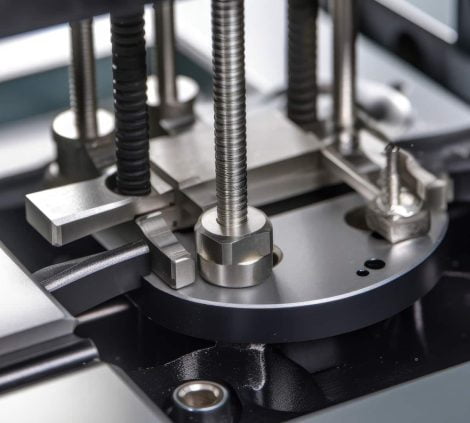

To complement our engineering and quality departments we have recently invested in a dedicated pressure testing station. Pressure testing is vitally important for any application to ensure that the components that have been installed are of the highest quality, and strength, whilst ensuring the reliability and durability of the part. Find out more about our pressure testing capabilities below, or contact us today to discuss your requirements.

Our investment in new technology combined with the ability to design and manufacture bespoke fixtures in-house means Advanced Engineering is capable of streamlining your subcontract processes under one roof.

Pressure testing is the process of using a range of pressure testing methods to identify weaknesses in a component, to ensure quality and robustness. One method of testing is non-destructive, meaning that the part isn’t damaged or altered during the process. Pressure testing is ideal for detecting top-level and sub-level issues with the material and is an extremely important part of the manufacturing process, as it ensures safety and reliability.

There are a range of benefits to pressure testing for your application:

Our experienced team here at Advanced Engineering have a wealth of knowledge in pressure testing components for a range of applications. We understand the importance of quality parts and thorough testing to ensure your applications run as smoothly as possible with no complications.

If you are interested in our pressure testing capabilities for your parts or application, get in touch with the team today for more information or to discuss your requirements.